Project

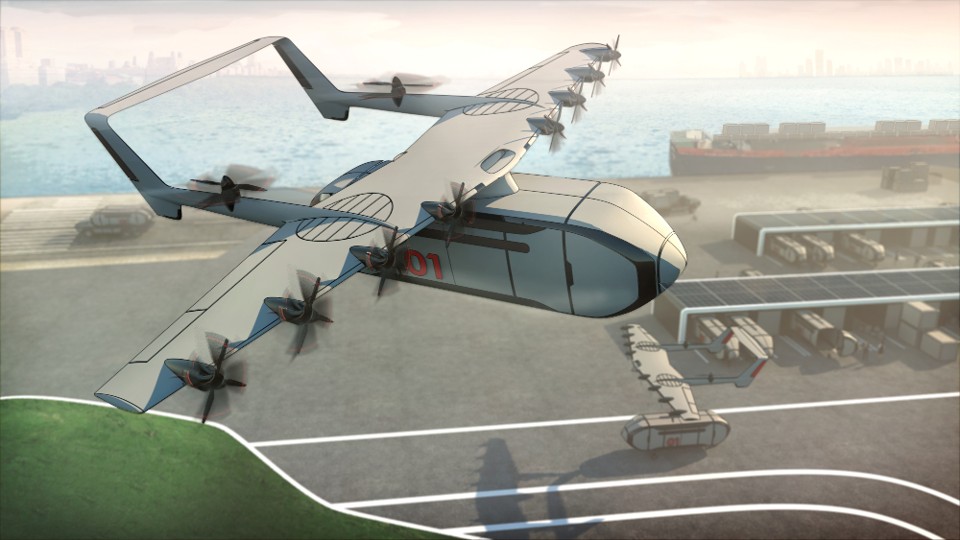

FlexCraft - Modular STOL Aircraft Design

Gold award-winning flexible aircraft platform for passenger transport, cargo, and search & rescue operations

Overview

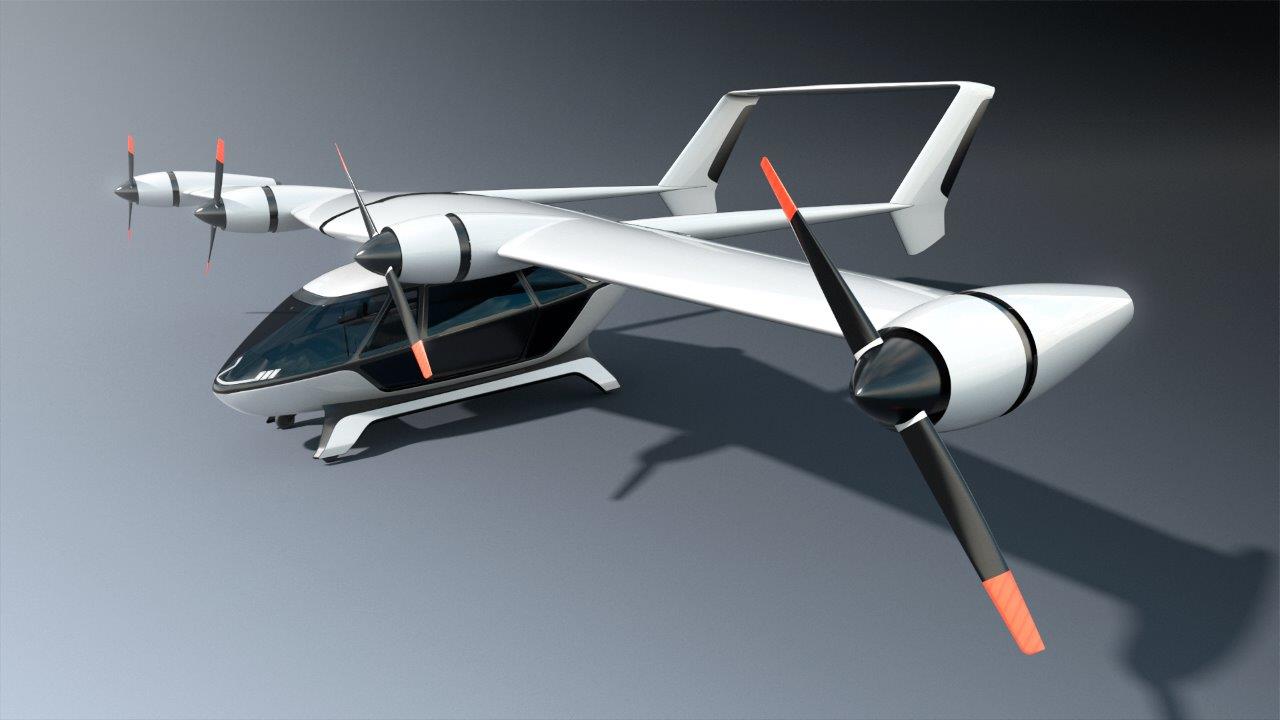

FlexCraft is an innovative STOL (Short Take-Off and Landing) aircraft that addresses the aeronautical industry's electrification challenge through a unique modular approach. The design uncouples the flight module (lift and propulsion) from interchangeable load modules, creating a flexible platform capable of serving as a passenger hub feeder, cargo transport, or search and rescue vehicle. This EU Horizon 2020-funded research project brought together an international consortium to demonstrate the viability of mission-adaptive aircraft design.

The Challenge

The aeronautical industry has long struggled with designing for electrification, particularly balancing battery energy density with weight reduction to achieve practical operational range. FlexCraft addresses this through an innovative modular architecture, but this flexibility introduced unique design challenges:

- Design cockpit for both piloted and autonomous configurations

- Balance battery energy density with weight reduction for optimal range across mission types

- Incorporate propulsion suitable for hybrid electric power-trains

- Accommodate varying operational requirements without compromising safety or usability

- Understand composite construction tenchnologies for fuselage and wing sections.

My focus centered on concept arquitecture and a passenger experience that could adapt across mission profiles. I also created exhibition mockups for major industry showcases where we needed to communicate the flexible platform concept to stakeholders.

My Approach

This project started as many new startups released eVTOL (Electric Vertical Takeoff and Landing) concepts around the world, answering Uber's white paper challenging private companies to develop the electric alternative to the helicopter. Working with Embraer, a giant in the commercial aviation sector, presented a unique learning oportunity, both n the operational and manufacturing aspects for us present our own answer.

With 4M+ euros in funsing secured, our three year journey took us from sketchbook to renders, manufactured wing sections, flying scale model, full scale fuselage mockup, and an official release at the prestigious Paris Air Show at Le Bourget.

What I did:

- Collaborated with engineering consortium (INEGI, IST, SET, EMBRAER) to understand technical constraints and mission requirements

- Designed instrument panel to accommodate multiple operational modes while maintaining pilot familiarity

- Designed interactive passenger elements

- Developed modular interface approach that adapts to passenger transport, cargo, and SAR missions

- Planned full-scale fuselage mockup for Instituto Superior Técnico unveiling

- Designed exhibition stands for Paris Air Show 2019 to communicate modular concept

- Coordinated physical mockup fabrication and installation for industry showcases

Key Design Decisions

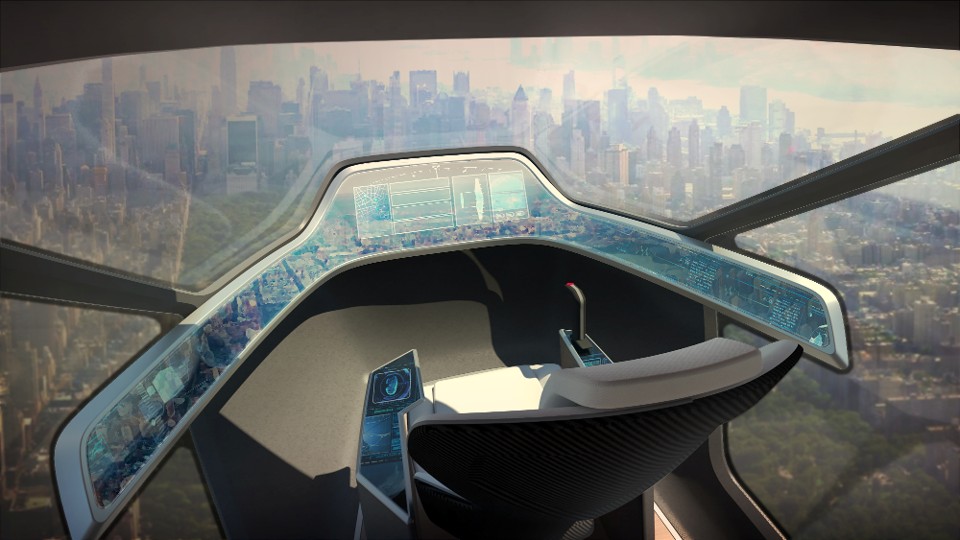

Modular Mission-Adaptive Instrument Panel

The problem: Traditional aircraft cockpits are designed for single mission profiles, but FlexCraft needed to serve passenger transport, cargo operations, and search & rescue missions—each with distinct information requirements and control priorities. A one-size-fits-all cockpit would compromise usability for all missions.The solution: Designed a flexible instrument panel architecture with reconfigurable displays and modular control layouts. Core flight instruments remain consistent for pilot familiarity, while mission-specific interfaces (passenger cabin management, cargo monitoring, SAR coordination) adapt based on the loaded module.

Why it works: Pilots develop muscle memory with core flight controls while gaining access to mission-specific tools only when relevant. The modular approach reduces cognitive load by presenting only applicable information for the current configuration.

Exhibition Mockups

Challenge: Stakeholders at Paris Air Show and technical showcases needed to physically experience the flexibility rather than just see renderings or diagrams. Without tangible demonstration, the innovation would be difficult to communicate.

Response: Designed and planned full-scale mockup showcasing the flight module with interchangeable load module concept. The exhibition stands at Paris Air Show and Instituto Superior Técnico were designed to facilitate walk-throughs, allowing visitors to see and touch and even sit inside the cabin.

Analysis: Physical presence generated significantly more stakeholder engagement than presentations alone. Industry professionals could evaluate build quality, understand the modularity mechanism, and envision operational applications through direct experience.

Dual-Mode Pilot/RPV Configuration

Challenge: FlexCraft needed to support both traditional piloted operations and remotely piloted vehicle (RPV) configurations for different mission scenarios, but these modes have fundamentally different control requirements and interface needs.Response: Designed instrument panel with provisions for both human pilot operation and autonomous/remote control integration. The interface architecture allows the same physical space to accommodate pilot instruments or RPV communication and monitoring systems without requiring structural redesign.

Analysis: The flexible design future-proofs the platform as autonomous aviation technology matures, while maintaining traditional piloted capability for current operational contexts and regulatory environments.

Horizon2020

Working within the Horizon2020 framework present unique challenges, chief of which was the effecitve collaboration between multiple organisations based at different locations. Meetings had to be very well documented and action items and milestones recorded. Regular reports were written in order to unlock portions of the total project funding by the European Comission.

Working withn these _Work Packages_ was an incredibly value project management experience that served me well for subsequent research and comercial projects alike.

Outcome

Recognition:

- IDA Design Awards Gold Winner 2018 - Transportation Design category

- International recognition validating innovative modular approach

- Congratulations to entire team: ALMADESIGN, INEGI, IST, SET, EMBRAER (PT)

- Successfully showcased innovative modular aircraft concept to global aviation industry at premier events

- Demonstrated viability of flexible platform approach through full-scale mockup

- EU Horizon 2020 funding validated innovation potential and research direction

- Exhibition design facilitated productive stakeholder engagement with operators and manufacturers

- Generated industry interest in modular aircraft economics and operational flexibility

- Physical mockup enabled detailed technical evaluation impossible through documentation alone

Impact:

What I learned: Working on an EU-funded research aircraft taught me how to design for flexibility without compromising mission-critical functionality—every design decision required balancing adaptability with safety and usability. The exhibition experience reinforced the importance of physical mockups in communicating complex technical innovation; stakeholder engagement increased dramatically when people could walk through and touch the aircraft rather than view renderings. Collaborating with an international consortium showed me how design bridges engineering disciplines—I served as translator between engineering, aerodynamics, human factors, and manufacturing concerns. I also learned that award-winning innovation often comes from questioning fundamental assumptions rather than incrementally improving existing approaches.

Get in touch for more information or to book a consulation.

Contact MeMore

Project

Eviation Alice - Electric Commuter Aircraft

World's first fully electric commercial airliner with bespoke glass cockpit design

World's first fully electric commercial airliner with bespoke glass cockpit design

See Project