Project

Eviation Alice - Electric Commuter Aircraft

World's first fully electric commercial airliner with bespoke glass cockpit design

01 Eviation Alice - First flight demonstration

Overview

The Eviation Alice represents a world first in aviation: a fully electric commercial airliner designed to revolutionize regional air travel. Charged with conceiving the cabin and cockpit for this groundbreaking aircraft, our team at Almadesign carried out extensive material and ergonomic studies, taking the project from initial design concept through to a working prototype showcased at the Paris Air Show at Le Bourget.

The Challenge

Designing for a world first in aviation presents unique challenges that go beyond traditional aircraft development. This required us to rethink cockpit and cabin design from first principles:

- Create a glass cockpit optimized for electric propulsion characteristics and energy management

- With our engineering partners, SETsa, conduct extensive material studies to balance weight reduction with structural integrity

- Design ergonomic solutions specific to electric flight operations and range considerations

- Coordinate prototype fabrication across international manufacturing partners

- Develop compelling exhibition experiences to communicate electric aviation's potential

- Integrate cutting-edge Garmin instrumentation into a fully bespoke cockpit design

My focus centered on pilot experience, resulting in a fully bespoke, top-of-the-range glass cockpit that prioritizes energy-aware flight operations while maintaining intuitive control interfaces.

My Approach

I collaborated with Eviation Aircraft and composite specialists Multiplast to design a cabin and cockpit experience suited to electric propulsion's unique operational characteristics.

What I did:

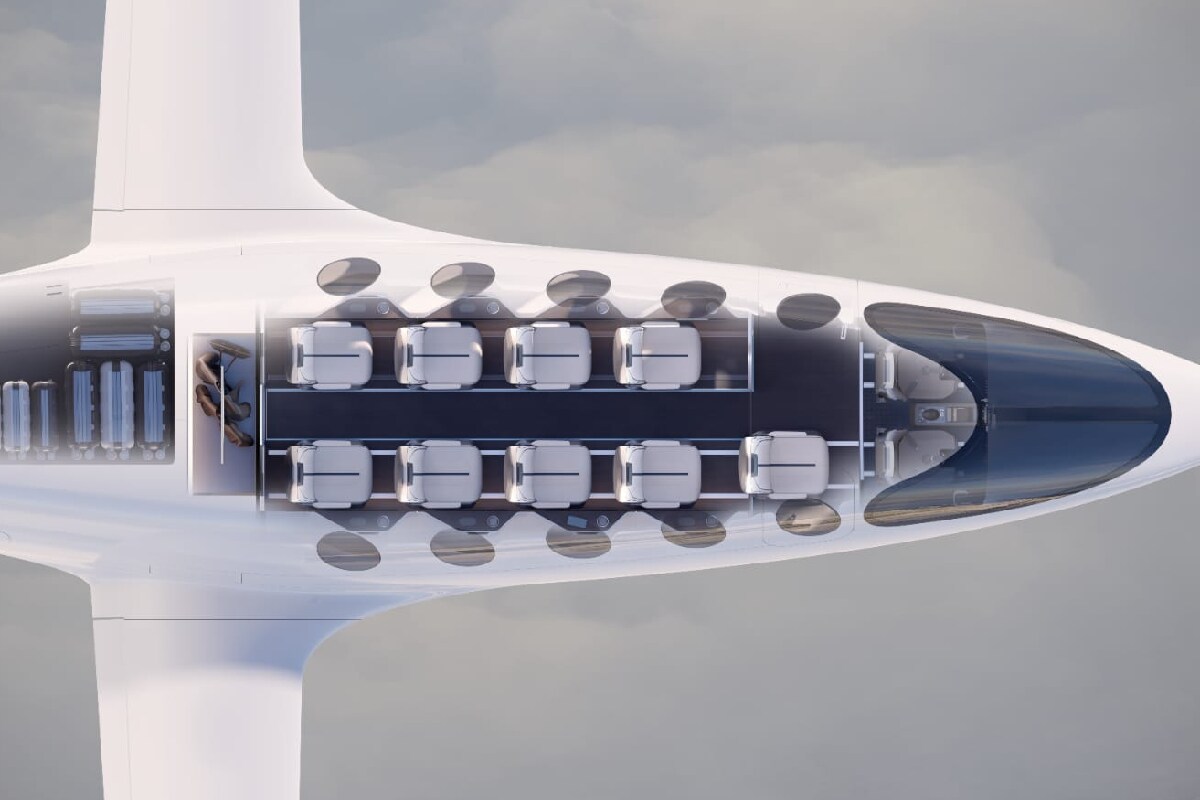

- Developed detailed cabin layout studies to optimize passenger confort and on-board stowage.

- Designed fully bespoke glass cockpit layout optimized for electric flight energy management

- Conducted ergonomic studies to optimize pilot interaction with electric propulsion systems

- Coordinated with Multiplast composite factory in Nantes overseeing cabin and cockpit assembly

- Developed full-scale cabin model and Unity-based VR experience for Paris Air Show exhibition

Key Design Decisions

Energy-Aware Glass Cockpit Interface

Issue: Electric aviation present extreme weight management challenges that can siginificantly reduce cabin and cockpit volume and so required us to question every assumption in order to find solutions. The pilot experience is also changed due to the fly-by-wire controls and the access to regenerative power systems.Response: Designed a bespoke glass cockpit integrating Garmin's advanced avionics with custom displays. Core flight instruments maintain familiar layouts for pilot confidence, while electric-specific fly-by-wire fligth controls grant the much needed design flexibility in a small space.

Prototype Assembly Coordination

Issue: Coordinating design intent across international manufacturing partners introduces communication challenges and risks design compromises during fabrication.

Reponse: I spent time at Multiplast's composite factory in Nantes, working directly with fabrication teams to oversee cabin and cockpit assembly. On-site coordination allowed real-time problem-solving, ensuring design specifications translated accurately to the assembly processes. Direct collaboration maintained design integrity.

Exhibition VR Experience

Issue: Electric aviation faces skepticism about viability, range, and passenger experience. At Paris Air Show, we needed to communicate the Alice's potential beyond static displays and technical specifications. Simply showing the aircraft wouldn't convey the experience of electric flight or help visitors envision regional electric aviation's future.Response: Developed a full-scale half-cabin model installed in the Le Bourget pavilion, paired with a Unity-based VR experience allowing visitors to experience a virtual electric flight. The VR simulation demonstrated silent electric propulsion, showcased the cabin's spaciousness, and illustrated typical regional routes the Alice could serve. The combination of physical mockup and immersive virtual experience made electric aviation tangible rather than theoretical.

Visitors could physically sit in the cabin while virtually experiencing flight, creating memorable associations between the actual aircraft and its operational potential. Industry stakeholders left with concrete understanding of electric aviation's near-term viability rather than abstract concepts.

Trade-offs & Constraints

International collaboration across Almadesign, Eviation, Multiplast, and SETsa introduced coordination complexity—design iterations required synchronization across time zones and organizational priorities. Exhibition timelines at Paris Air Show drove rapid prototyping decisions, sometimes requiring pragmatic choices over ideal solutions to meet unveiling deadlines. The pioneering nature of electric commercial aviation meant we lacked operational data from existing fleets—design decisions required educated projections about pilot needs rather than proven experience. Prototype assembly at Multiplast's facility in Nantes required on-site presence, but budget and schedule constraints limited the time I could spend coordinating directly, necessitating detailed documentation and remote coordination for some assembly phases.

Outcome

Recognition:

- Successfully showcased world's first all-electric commuter aircraft at Paris Air Show 2019

- Generated significant industry attention validating electric aviation's commercial potential

- Established design language for electric aircraft cockpits balancing energy awareness with pilot familiarity

- Eviation Alice completed successful flight tests, proving electric commercial aviation viability

- The aircraft is en route to fulfill the promise of sustainable regional air travel

- Bespoke glass cockpit design demonstrated how electric propulsion can integrate with proven avionics

- VR exhibition experience successfully communicated electric flight benefits to stakeholders and public

- Material studies and composite fabrication coordination achieved weight targets critical for electric range

- Full-scale cabin model generated tangible engagement impossible through renderings alone

Impact:

What I learned: Designing the world's first electric commuter aircraft taught me that pioneering aviation requires balancing innovation with proven reliability, so electric-specific features needed to feel like natural extensions rather than radical departures. Spending time at Multiplast's factory reinforced that weight-critical composite fabrication benefits enormously from designer presence during assembly; what seems clear in CAD can be ambiguous on-site and problem-solving prevented design compromises. The VR experience showed me the power of experiential demonstration for skeptical stakeholders—letting people "fly" electrically generated more conviction than technical specifications. Finally, seeing the Alice complete flight tests validated that thoughtful cockpit design contributes to operational success—the interface we created helps pilots manage electric flight's demands while maintaining the safety standards aviation requires.

Get in touch for more information or to book a consulation.

Contact MeMore

Project

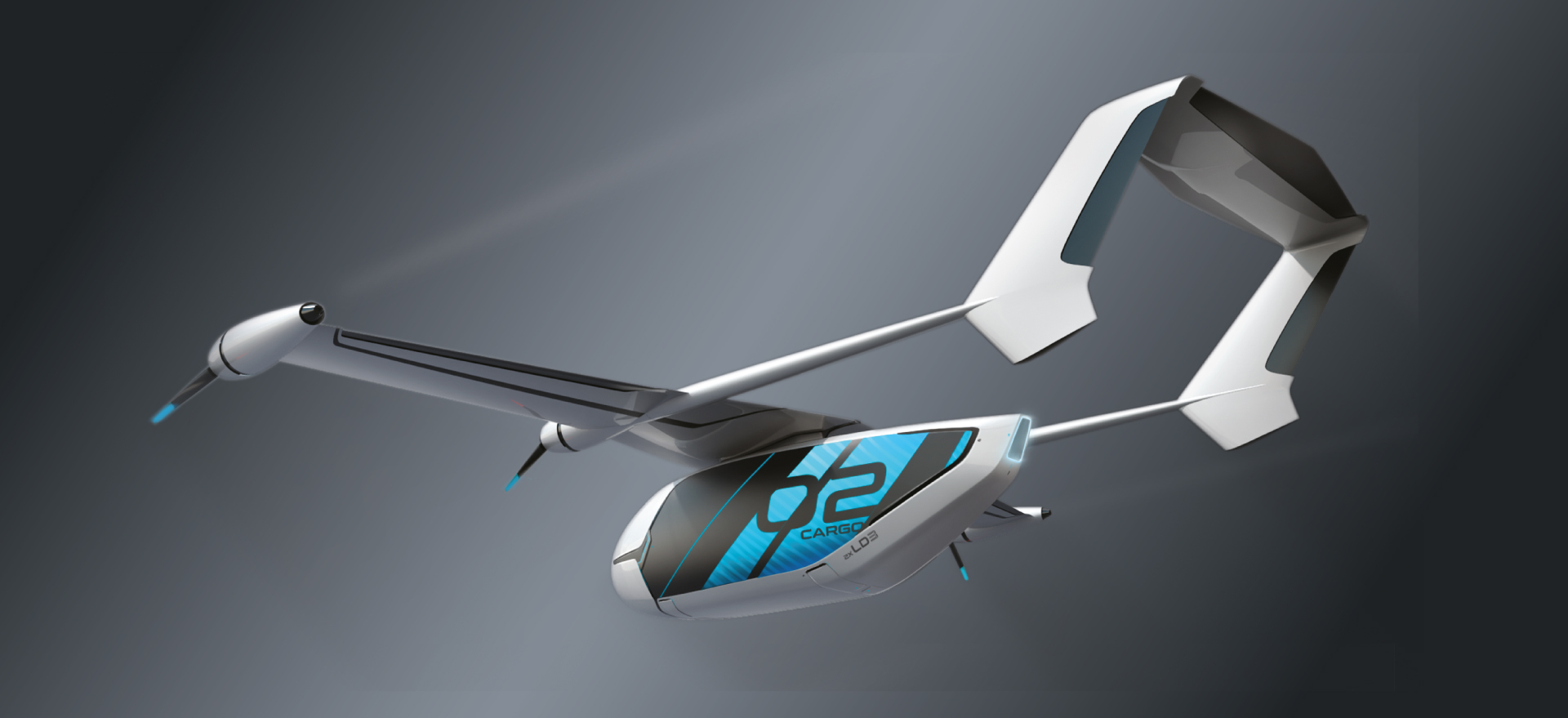

FlexCraft - Modular STOL Aircraft Design

Gold award-winning flexible aircraft platform for passenger transport, cargo, and search & rescue operations

Gold award-winning flexible aircraft platform for passenger transport, cargo, and search & rescue operations

See Project