Project

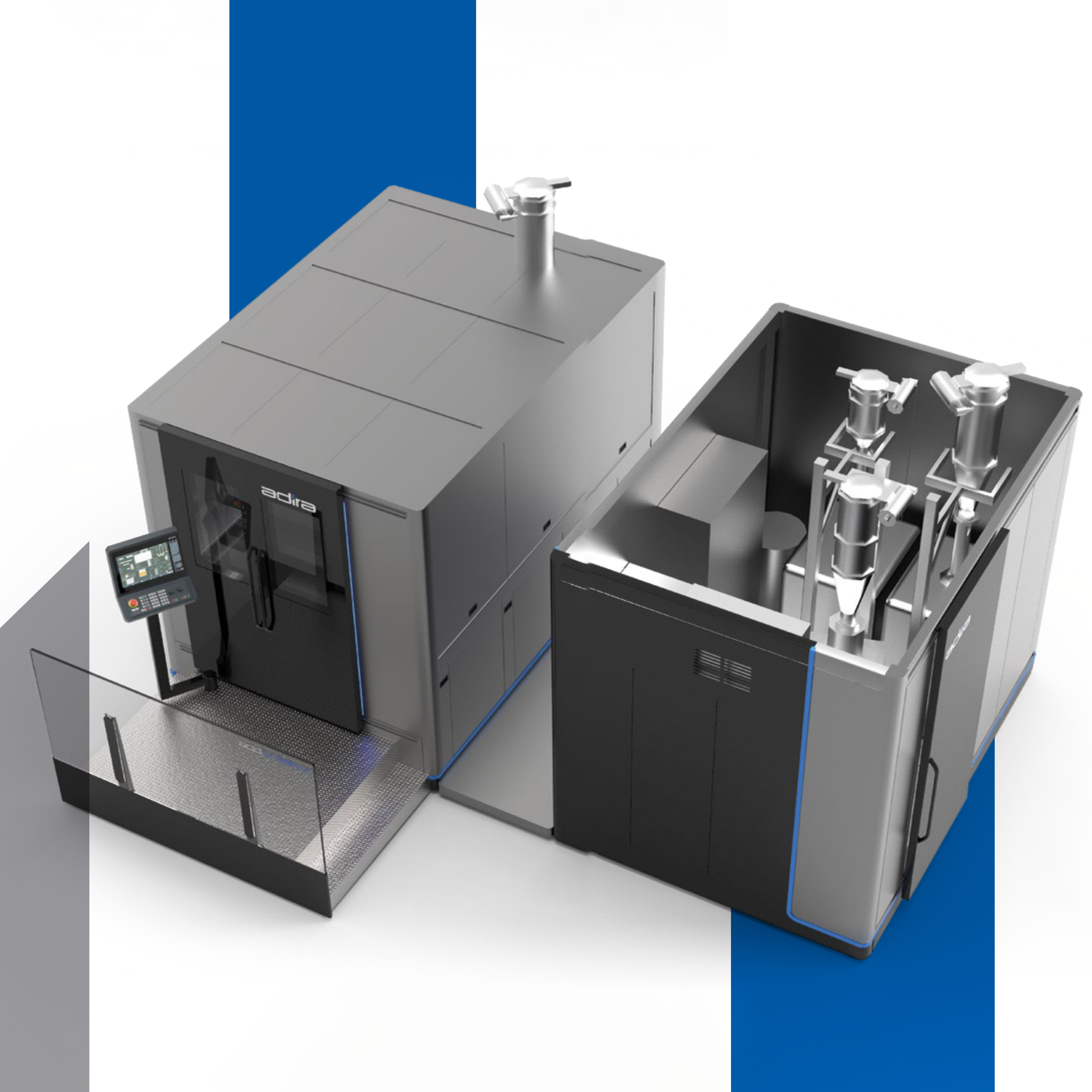

Adira ADDCREATOR

World's largest metal 3D printer using revolutionary Tiled Laser Melting technology

Overview

The Adira ADDCREATOR represents a breakthrough in additive manufacturing, featuring revolutionary Tiled Laser Melting (TLM) technology developed in partnership with Fraunhofer Institute for Laser Technology. This system enables metal 3D printing at unprecedented scales, with a build volume of 1000 x 1000 x 500mm, producing parts up to three times larger than any other machine on the market.

My role, as part of the Almadesign team, encompassed UI/UX design for the control systems, industrial design of the machine housing and lighting, and 3D modeling and rendering of the concept throughout development.

Revolutionary Technology

Tiled Laser Melting (TLM)

The ADDCREATOR uses a revolutionary approach based on a mobile process chamber that efficiently ensures all necessary conditions for Laser Powder Bed Fusion (LPBF) with an area much smaller than the powder bed. Each layer is divided into sections (tiles) that are sequentially processed by the mobile process chamber.

This method allows for extra-large builds with many more parts than a conventional LPBF machine in a single run, and enables parts to be built at sizes that would simply not be possible with other machines. As a modular and scalable concept, there is no limit beyond the size of your ambitions.

Key innovations:

- Multi-laser system: 4 fiber lasers with partial overlap (400-1000W per laser)

- On-the-fly processing: Lasers work continuously while the chamber moves, eliminating dead time

- Removable build platform: Minimal downtime between build jobs

- Automated powder circulation: Closed-loop system with integrated sieving

- Independent layer applicator: Faster coating cycles with uniform layer deposition

Design Challenge

Designing for the world's largest metal 3D printer presented unique challenges:

- Scale complexity: Creating a user interface that manages a build volume 3x larger than competing systems while maintaining operator confidence

- Manufacturing environment: Housing and lighting must work in industrial conditions while maintaining accessibility for maintenance

- Advanced technology communication: Making revolutionary TLM technology understandable to operators familiar with traditional LPBF systems

- System integration: Coordinating UI with multi-laser systems, automated powder handling, and process monitoring

- Visual identity: Expressing technological leadership through industrial design language

My Approach

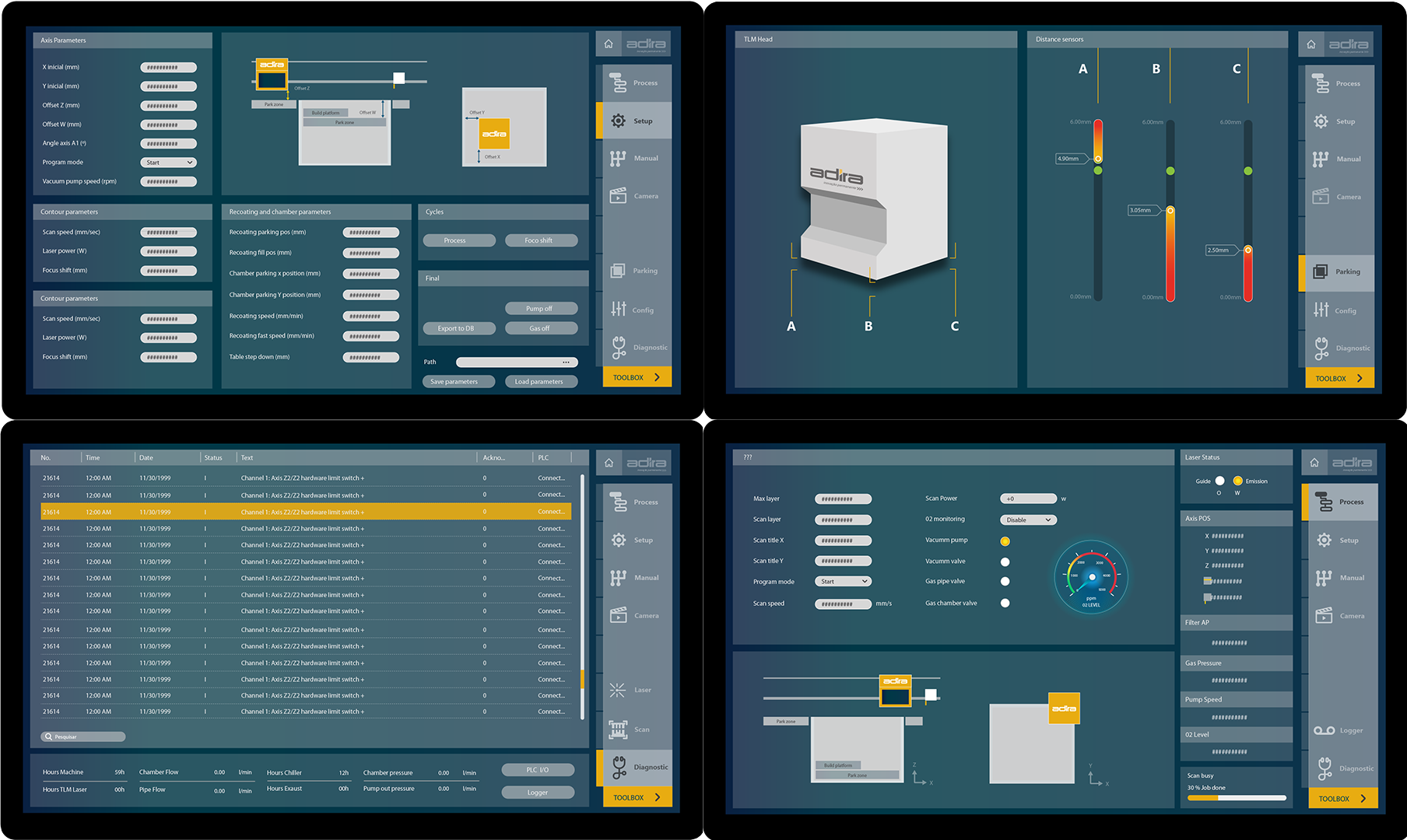

UI/UX Design

I designed the control interface to manage the complexity of TLM technology while supporting operator workflows in demanding manufacturing environments. The interface needed to communicate multi-laser coordination, tiled processing status, powder system automation, and real-time process monitoring across a build platform significantly larger than operators were accustomed to.

Key focuses included:

- Real-time visualization of tiled laser melting process

- Automated powder circulation system controls

- Build job timeline with phase transitions

- Alert hierarchy optimized for critical manufacturing workflows

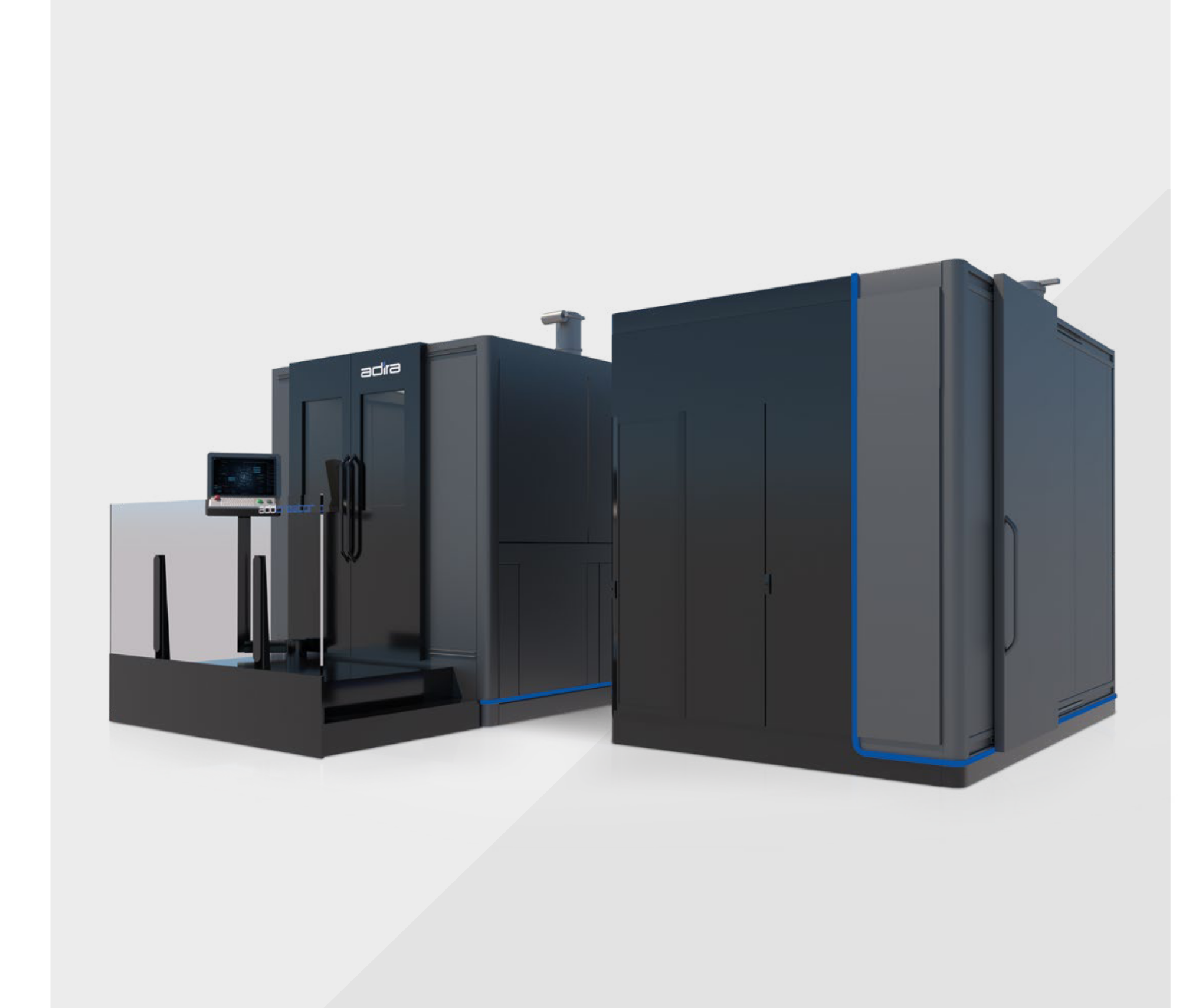

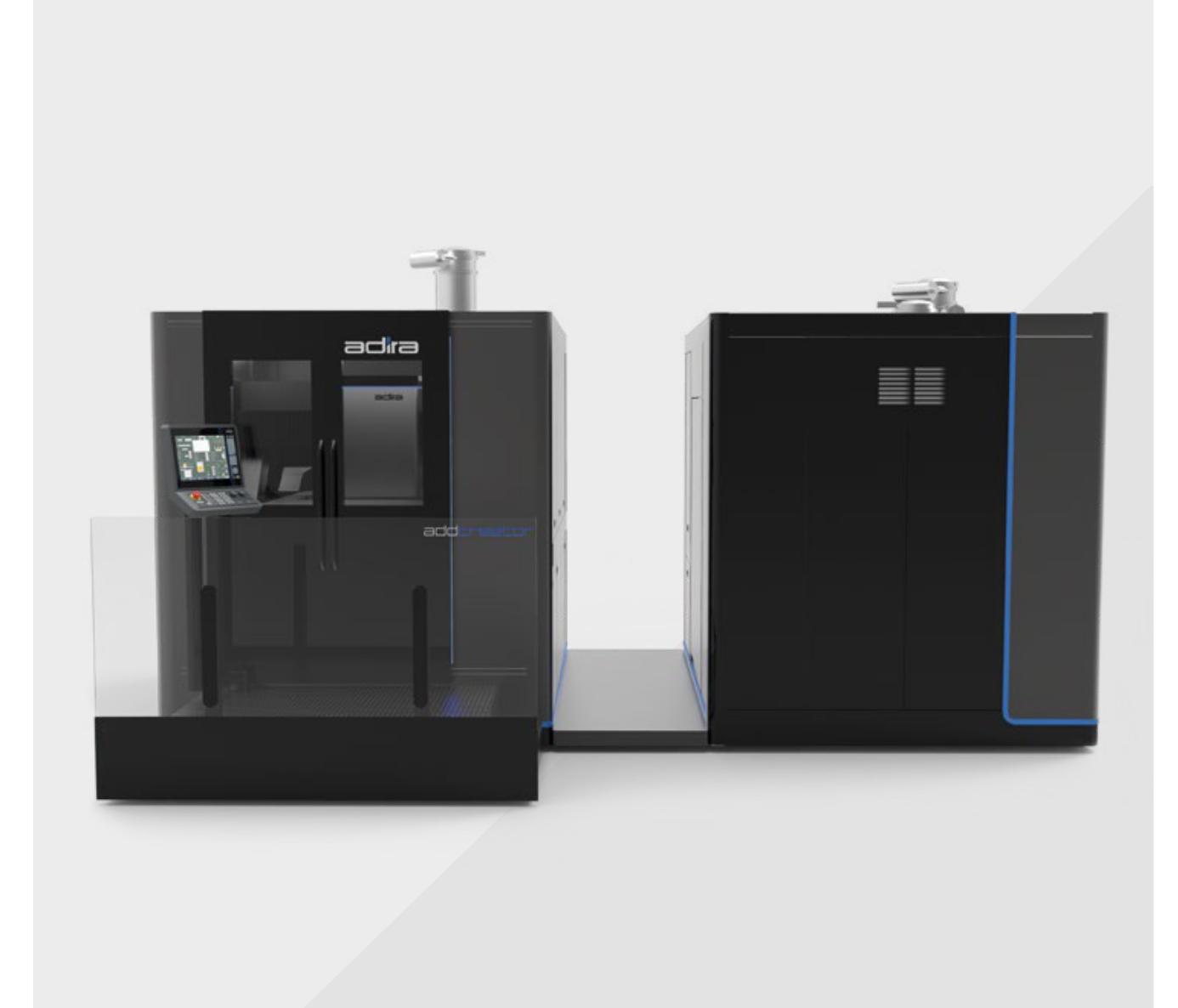

- Overall form language communicating innovation and precision

- Access points for maintenance and powder handling

- Lighting design for operational visibility and safety

- Visual integration of modular components

- Distinctive blue accent elements establishing brand identity

Industrial Design

The machine housing design needed to express technological sophistication while supporting practical manufacturing requirements. I worked on:

3D Modeling & Visualization

Throughout the development process, I created 3D models and photorealistic renderings to communicate design concepts, evaluate proportions and access points, and produce marketing materials for a groundbreaking product in a specialized industry.

Technical Specifications

Build Volume: 1000 x 1000 x 500 mm (substrate included) Processing Field: 680 x 230 mm Layer Thickness: 50-150 µm Build Capacity: Up to 100 cm³/h Laser System: 4 fiber lasers, 400-1000W each Machine Dimensions: 8000 x 8500 x 4000 mm Control System: SIEMENS Sinumerik 840D

Outcome

Impact:

- Delivered the world's largest metal 3D printer with build volumes 3x larger than competing systems

- Enabled manufacturing of previously impossible part sizes

- TLM technology validated for industrial production environments

- Established Adira's position at the forefront of large-scale additive manufacturing

- Design language and UI patterns adopted across Adira's product line

Get in touch for more information or to book a consulation.

Contact MeMore

Project

Clean Sky 2 - Next Generation Cockpit

Reducing pilot cognitive load through adaptive interface design for a potential civilian Airbus C295

Reducing pilot cognitive load through adaptive interface design for a potential civilian Airbus C295

See Project